Our Top Courses

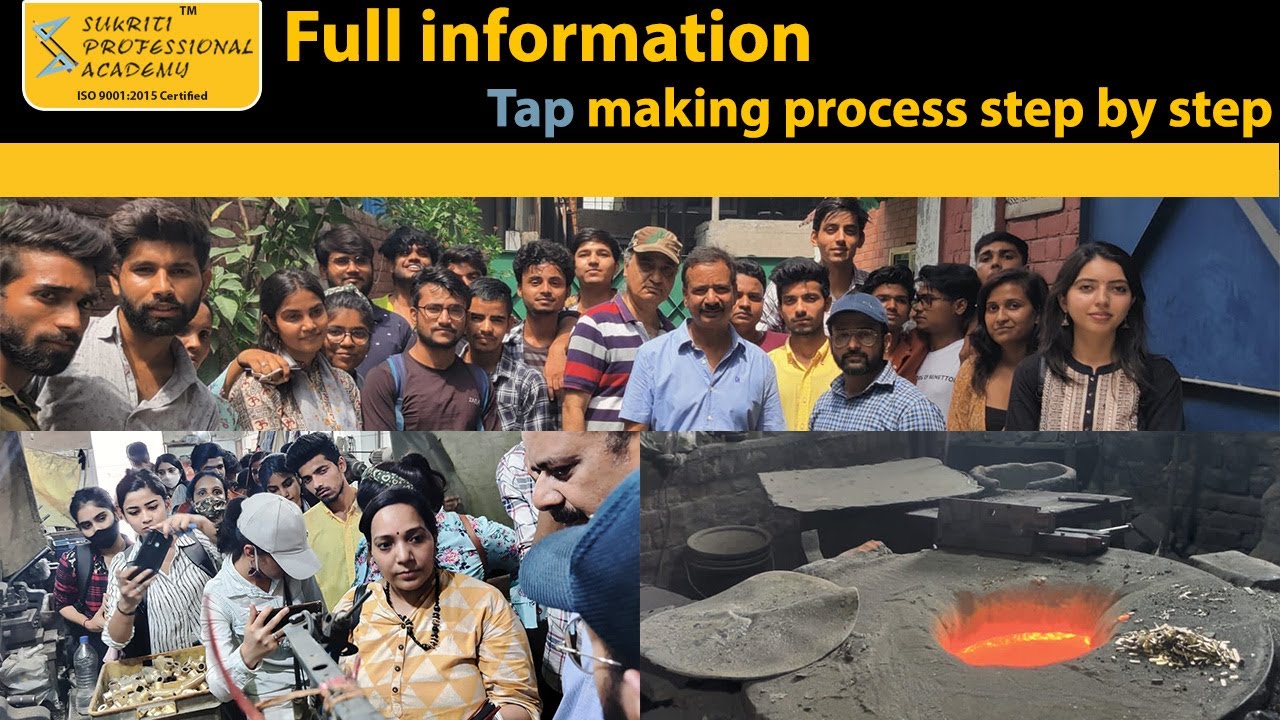

About Course

Why This Experience is Valuable

This course provides a unique and in-depth look into the fascinating process of tap manufacturing, from raw materials to the final product. Understanding how taps are made not only reveals the engineering, precision, and craftsmanship behind everyday fixtures but also equips you with essential knowledge about manufacturing standards, material selection, and quality control in plumbing and industrial design. Whether you’re a student, industry professional, or home improvement enthusiast, this course will give you valuable insights into the processes and technologies that create durable, functional, and aesthetically pleasing taps. By the end, you’ll be able to make more informed choices regarding tap quality, design, and sustainability in various applications.

Benefits of the course

- Material Selection and Preparation: Learn about the choice of materials like brass, stainless steel, and other alloys that make taps durable, rust-resistant, and safe for water flow.

- Casting and Molding: Explore the casting process, where metals are melted and shaped into the initial form of the tap through molds. This section covers both die-casting and sand-casting methods.

- Machining and Shaping: Understand how machines refine the rough cast into the precise shape and size, creating threads for the tap’s inner mechanisms.

- Polishing and Plating: See how taps are polished to create a smooth, shiny surface, then plated with chrome or other finishes for corrosion resistance and aesthetic appeal.

- Assembly of Components: Discover the assembly process where individual parts such as handles, spouts, cartridges, and seals are fitted together.

- Quality Control and Testing: Learn about the rigorous testing processes that ensure taps are leak-proof, durable, and meet industry standards for water pressure.

- Packaging and Distribution: See how the finished taps are cleaned, packaged, and prepared for shipping to customers and stores.